- +91 9860142383

- jjengg71@gmail.com

- F-II Block, Plot No. 17/2, M.I.D.C., Bhosari, Pune - 411 026, MH, India.

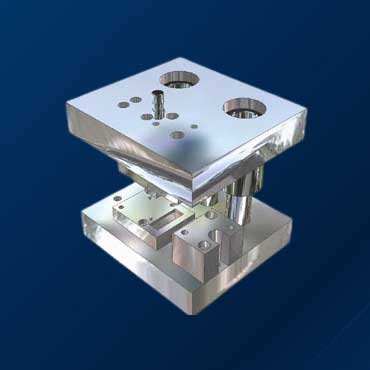

Press Tools

Press Tools

Industrial press tools are critical components used in manufacturing processes that involve shaping or cutting materials using a press machine. These tools are widely used in industries such as automotive, aerospace, electronics, and metalworking. Here’s an overview of industrial press tools, their types, and their applications:

Types of Press Tools

- Stamping Dies: Tools used to cut or shape material (usually sheet metal) using a press. They consist of two main parts: the punch (which pushes the material) and the die (which provides the shape).

- Bending Tools: Used to bend sheet metal or other materials into specific angles or shapes. Common types include V-bending, U-bending, and edge bending tools.

- Coining Dies: Used for high-precision forming where the material is shaped by squeezing it in a closed die set. This process is often used to produce coins or other detailed metal parts.

- Progressive Dies: These are a series of stations, each performing a different operation on the part, such as cutting, bending, or punching, as it moves through the die.

- Transfer Dies: Similar to progressive dies, but the part is transferred from station to station within the die; often used for larger parts.

- Compound Dies: Perform multiple cutting operations in one press stroke. They can cut the outside and inside shapes of a part in one operation.

Applications of Press Tools

- Automotive Industry: Manufacturing body panels, chassis components, and other metal parts.

- Aerospace Industry: Producing aircraft components with high precision and strength requirements.

- Electronics: Creating metal parts for electronic devices, such as housings and connectors.

- Household Appliances: Manufacturing parts for appliances like washing machines, refrigerators, and microwaves.

- Metal Furniture: Producing metal frames, brackets, and other components for furniture.